Easy-to-process all-roundersPiezoelectric materials

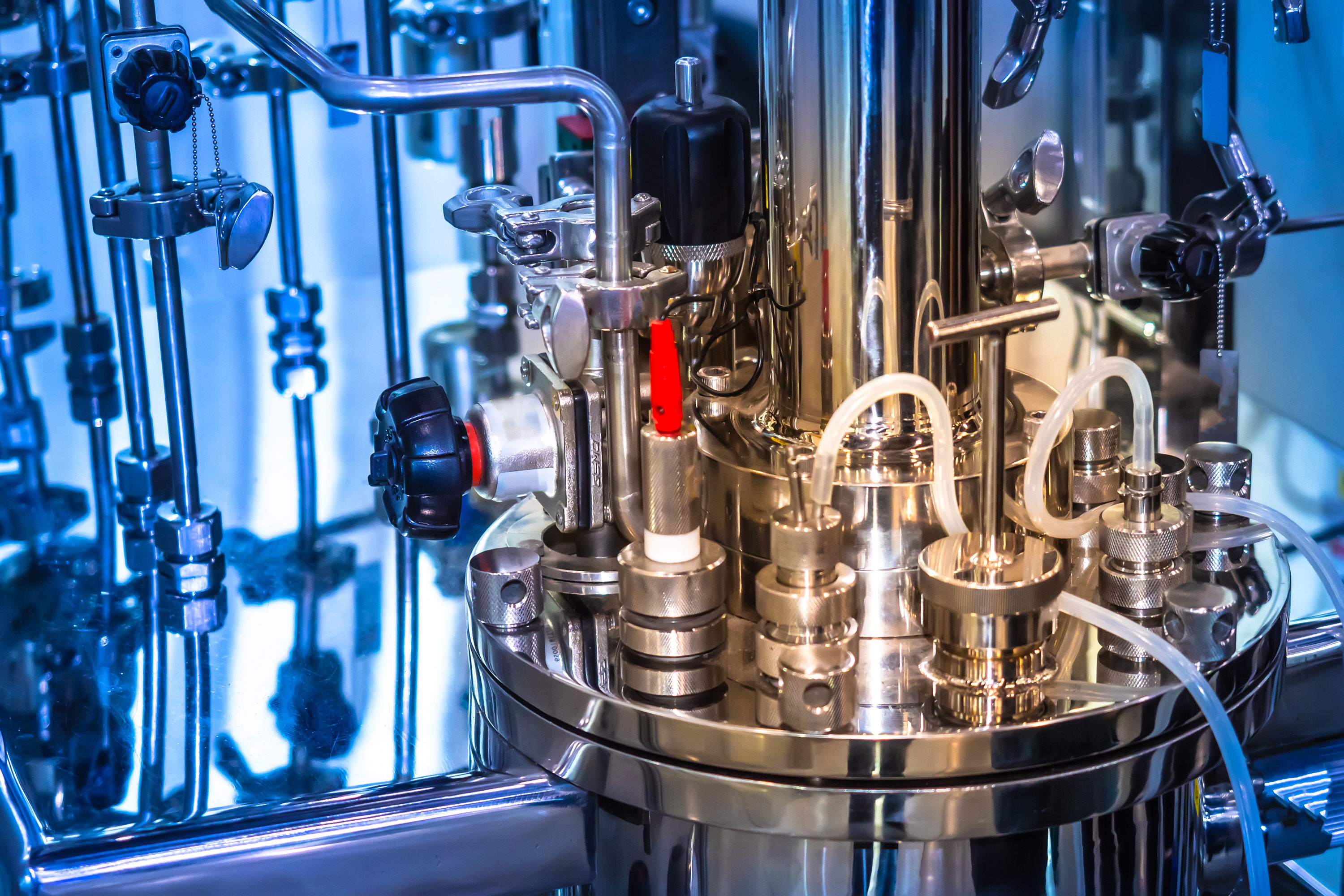

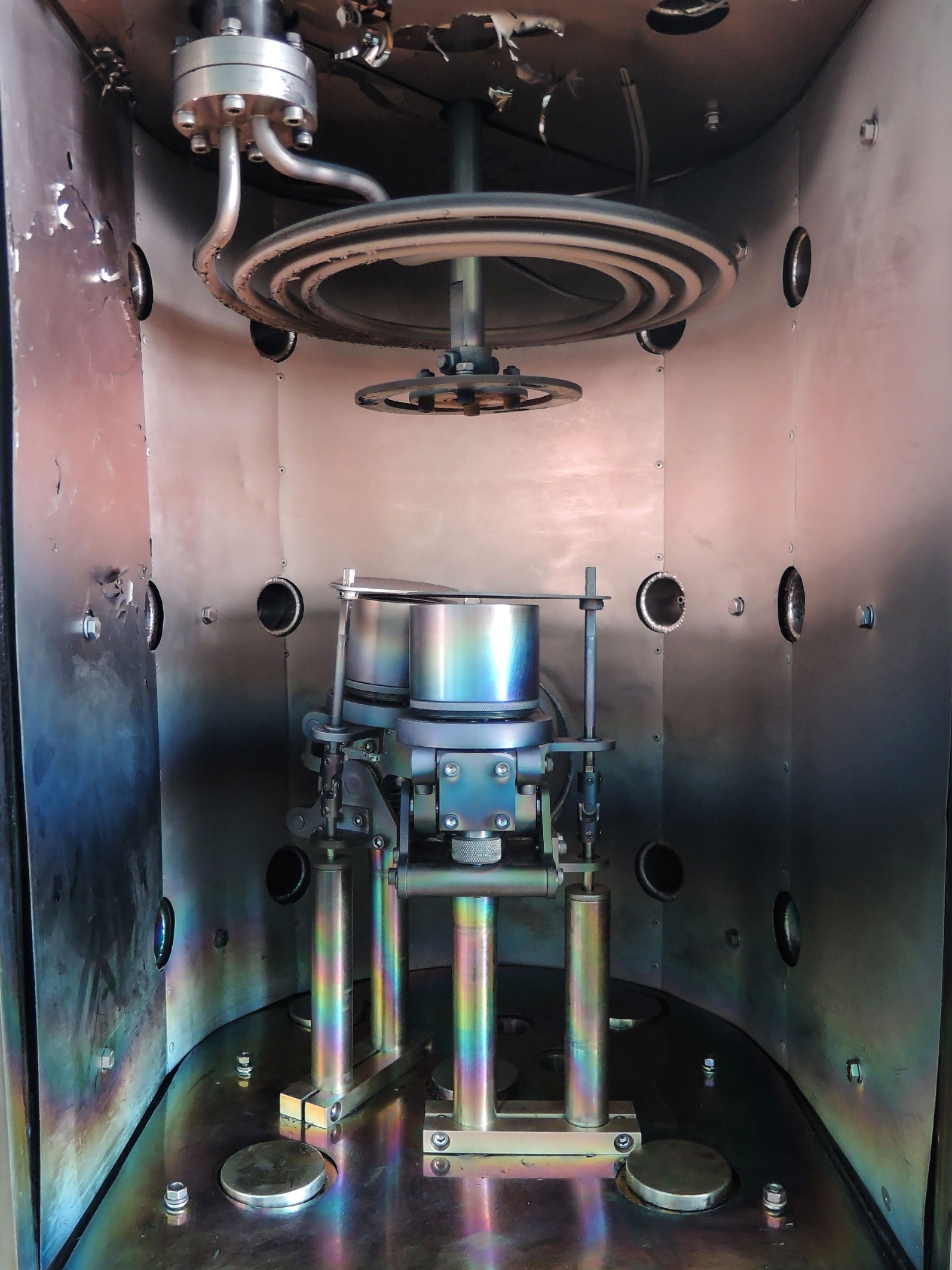

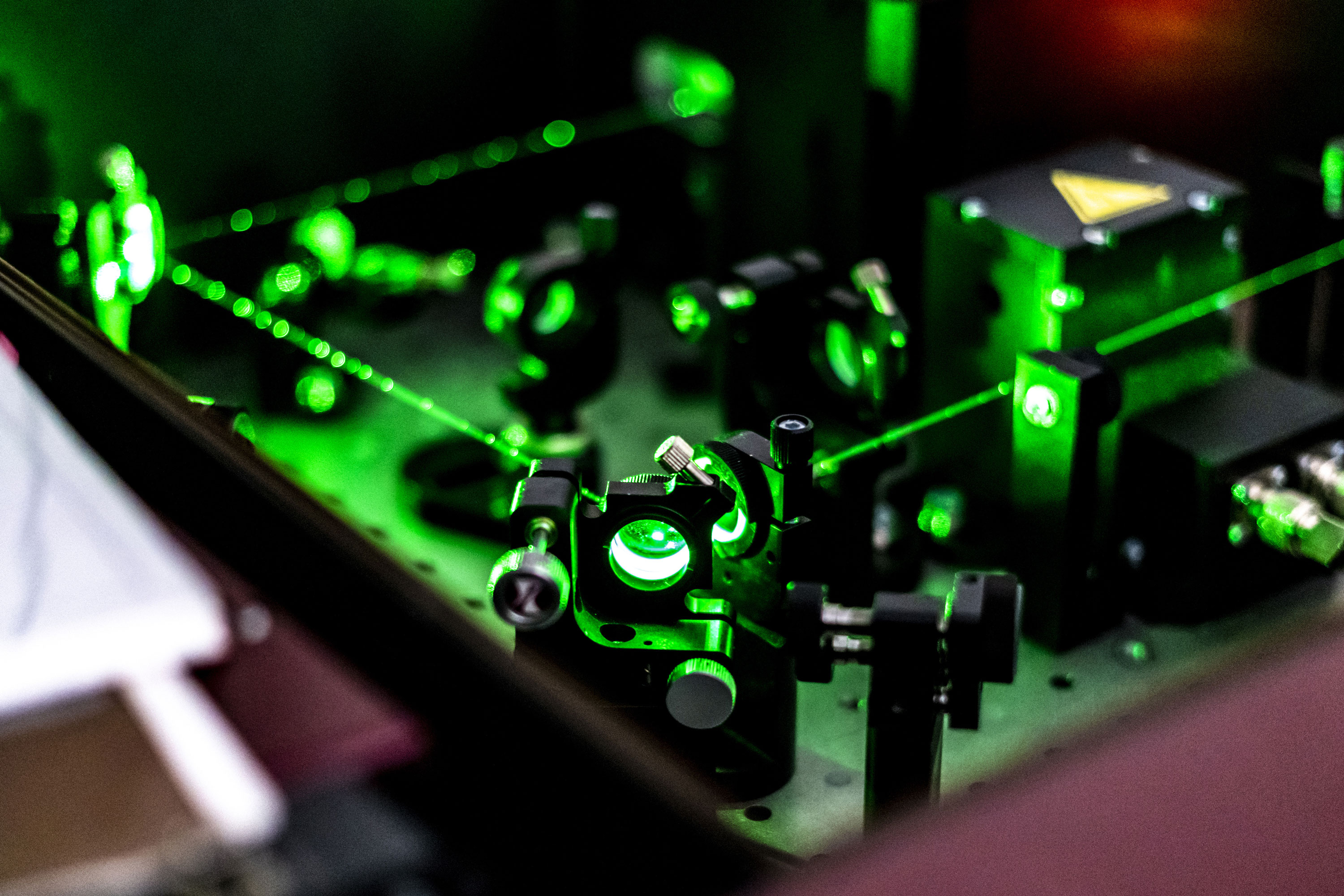

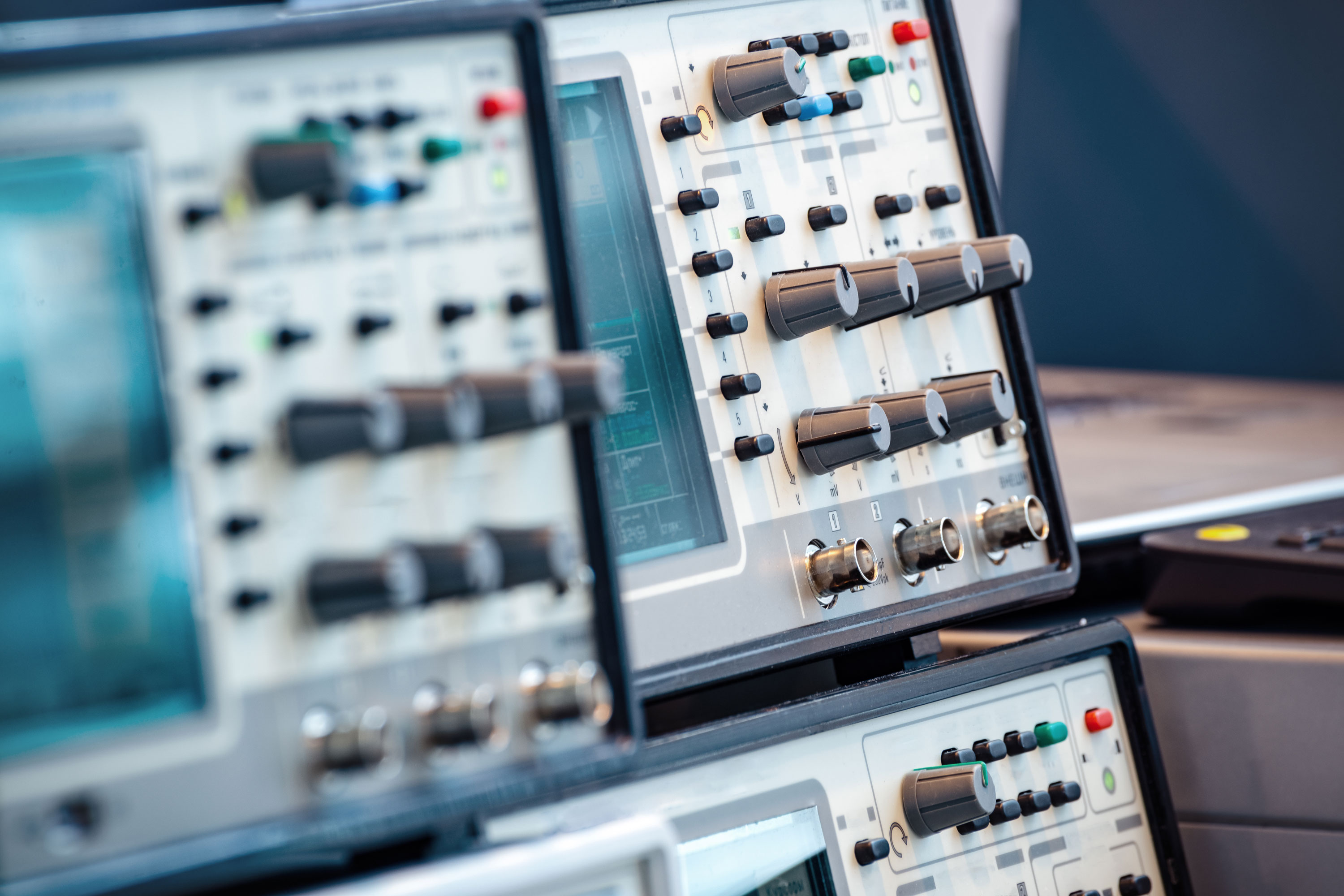

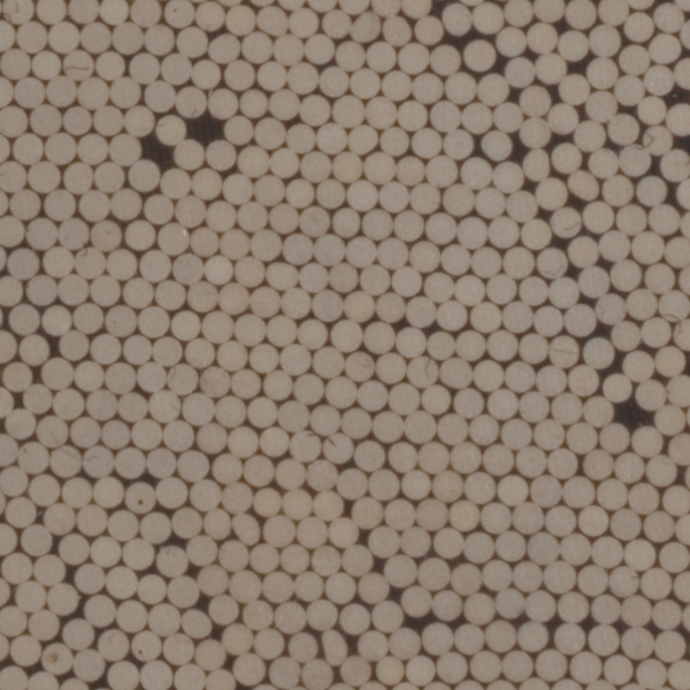

Sensors, actuators and ultrasonic generators: The three main areas of use for piezoelectric ceramics. These ceramics are used in modern plant engineering, in many areas of industrial process technology and in the entire field of research and development – such as for measuring acceleration data, for switch actuators and for a wide range of ultrasonic applications. For machining that is as precise as it is cost effective, the relatively easily machinable material has to be brought into the desired shape using various methods. Due to its hardness and brittleness, the work must be particularly precise and gentle on the material in order to minimise material loss and damage.

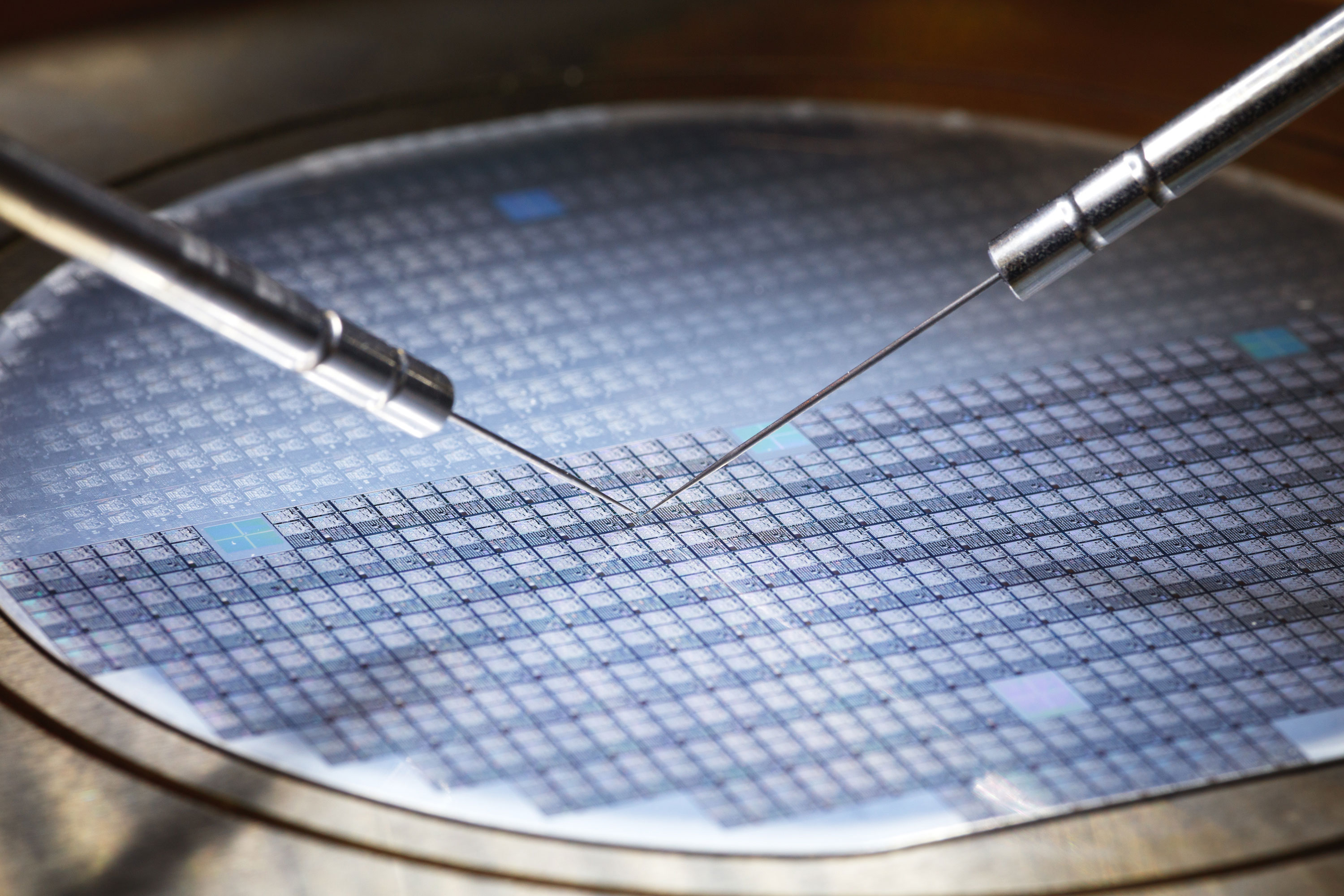

With a vast amount of care, experience and expertise, we process piezoelectric materials in very different ways. The machining methods we use include ID sawing, which is gentle on the material, and surface or plane grinding. As specialists in handling hard, brittle materials such as ceramics and composites, we use our modern 3- and 4-axis CNC machining technology to permit even complex, customised geometries.

Application cases

Sensors

Piezoelectric actuators

Ultrasonic generators

Properties

Piezoelectric materials

Good machinability in part