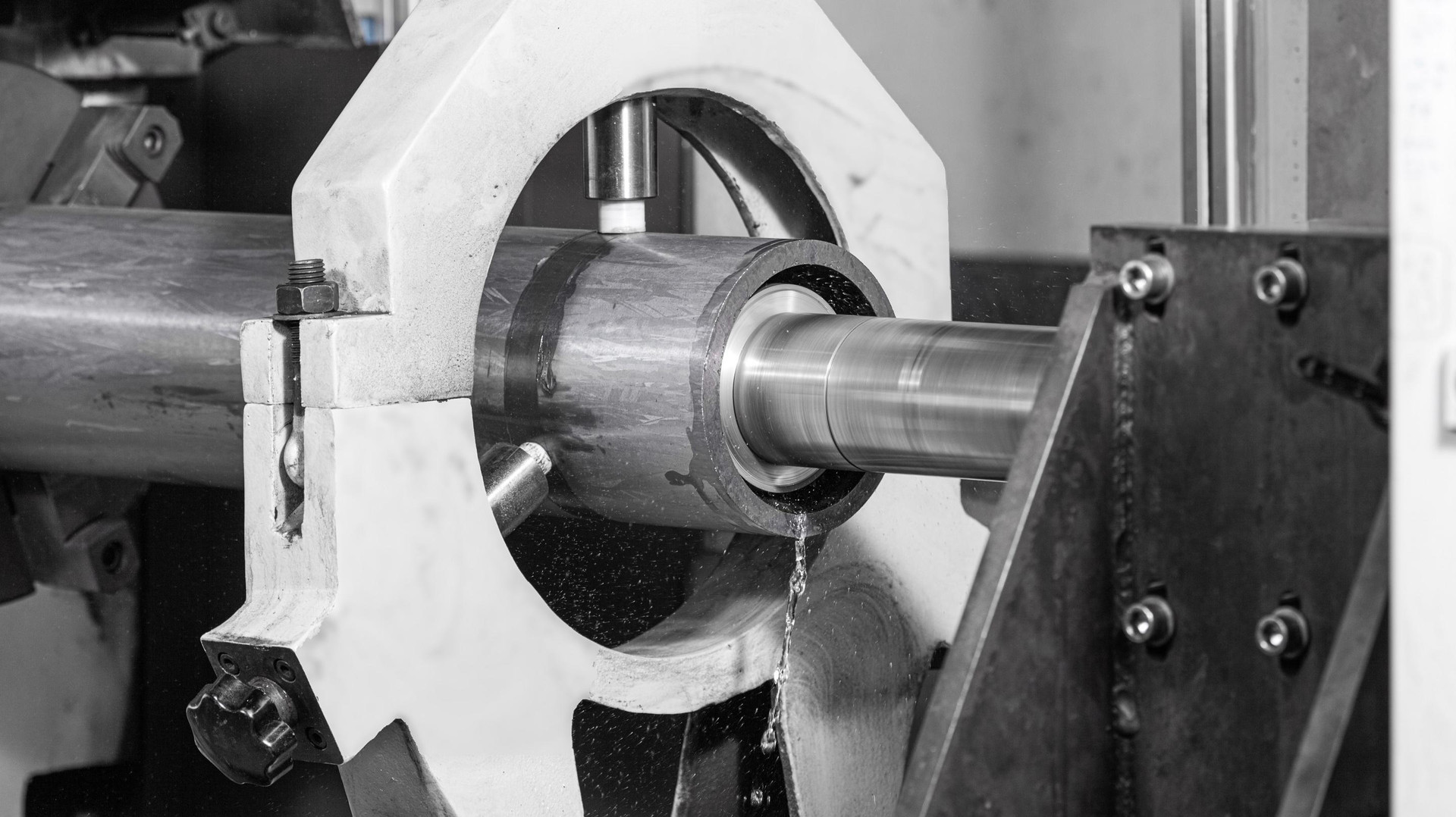

Precise and diverseInternal cylindrical grinding

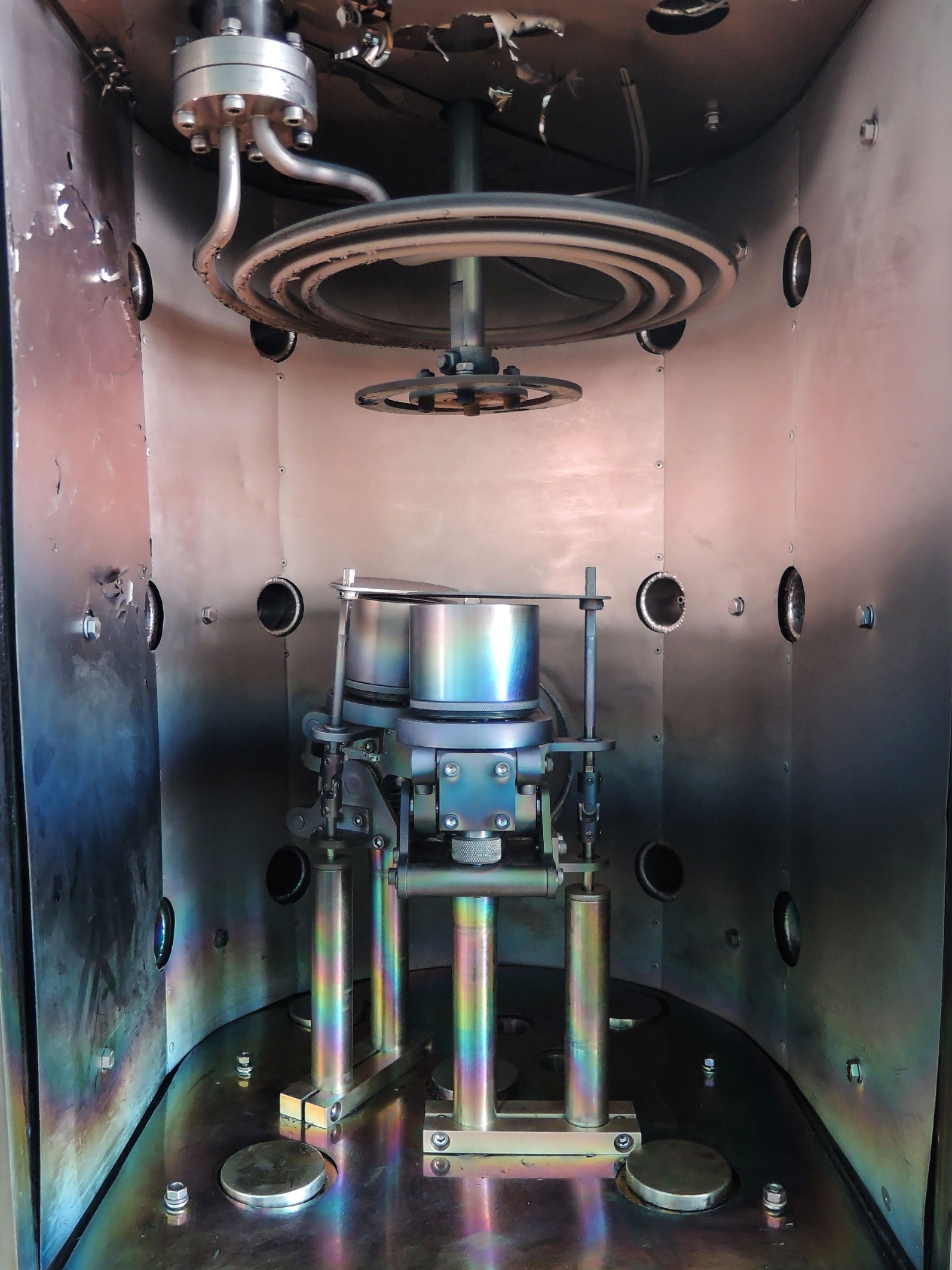

The mechanical process of internal cylindrical grinding enables rotationally symmetrical workpieces to be machined extremely precisely – for instance inner areas of tube segments that are hard to reach. This produces parts that are characterised by a particularly high-quality surface finish, which facilitates further processing. Typical applications include components such as tube targets, diffusion tubes, sleeves and the like. Besides the stability and precision of the grinding machine, the cooling of the workpiece is of particular importance.

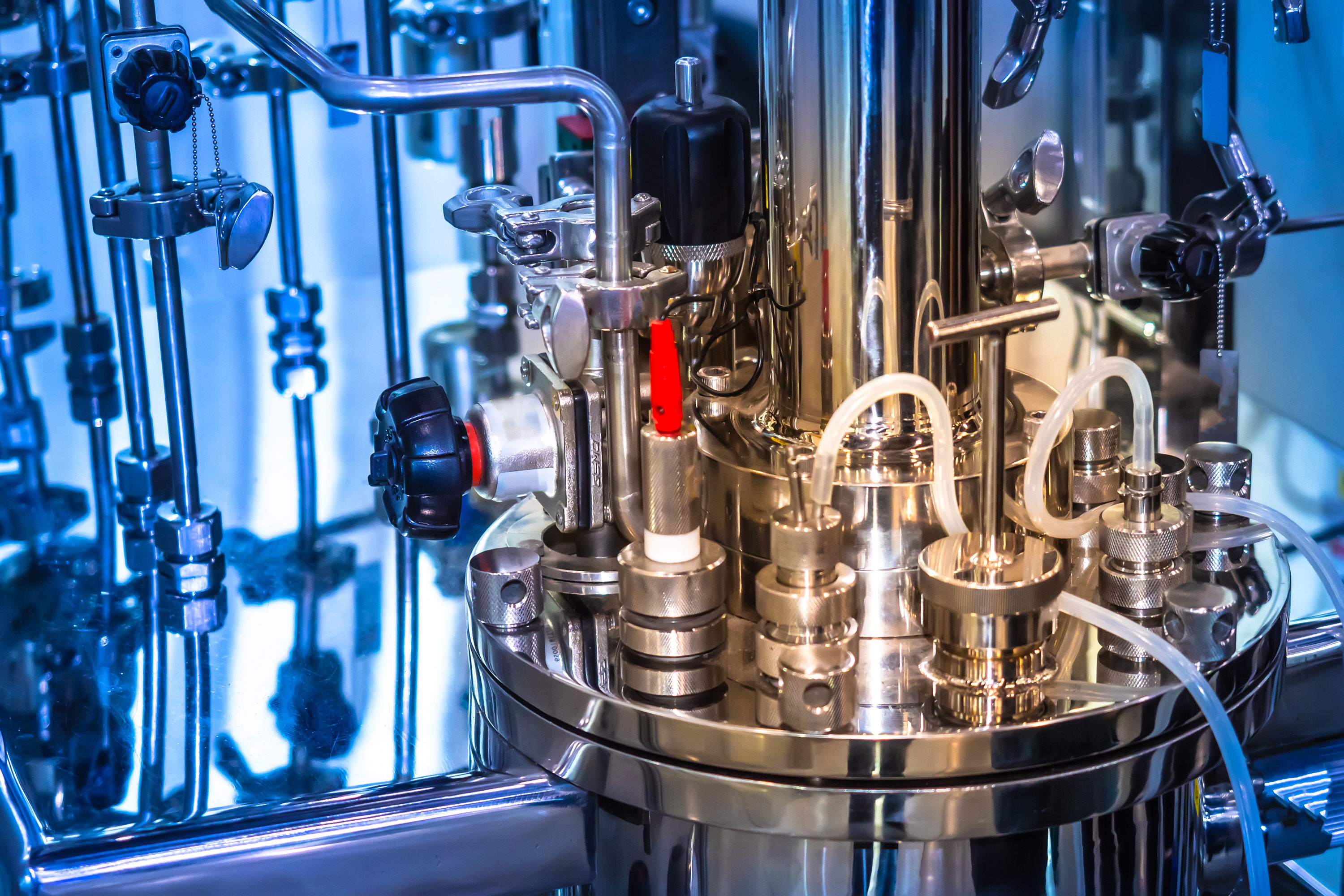

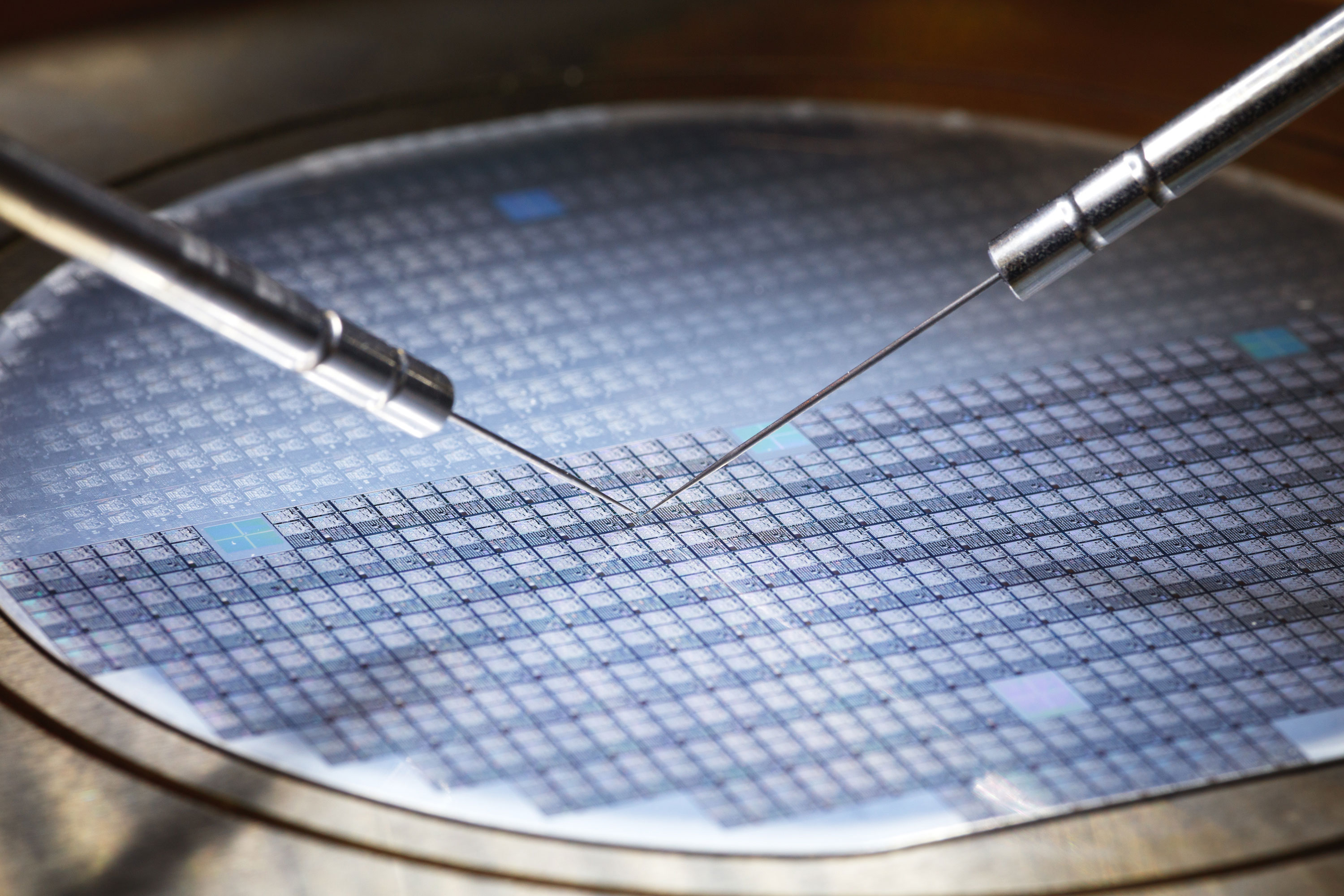

Machining is a demanding process, its challenges including the clamping and alignment of the workpieces. The grinding tools used must be selected and applied carefully, depending on the material. We can draw on a vast amount of experience and expertise in internal cylindrical grinding, enabling us to machine workpieces with sizes from less than 100 mm to up to 500 mm in diameter, and with lengths of up to 600 mm. In doing so, we excel with our immense flexibility and speed. We work for customers in various sectors, including optics and optoelectronics, semiconductor technology, process technology, the primary extractive industries, and research and development.

Facts

Very precise grinding method

Suitable for rotationally symmetrical workpieces

High-grade surface finish

Precise shaping for a wide range of materials

Technical data

Workpiece dimensions

Diameter (Ø): 100 mm to >500 mm

Dimensions: < 100 mm – >500 mm