Targets and structural componentsQuartz glass (SiO₂)

As a very versatile material, high-purity quartz glass plays an important role in the fields of plant engineering and process technology, in the semiconductor industry, the basic materials industry and in research and development. Quartz glass is also frequently used in modern metrology. At the same time, it is very resistant to many process atmospheres. It possesses good machinability in further mechanical processing.

We supply our customers with sputtering targets and a wide variety of individual quartz-glass structural components. In machining, we draw on our vast experience – and with our highly flexible machinery are able to offer all relevant machining techniques. This enables us to conduct highly precise cutting work by means of ID sawing, bandsawing, peripheral (OD) sawing and rotary sawing, working in a way that is gentle on the material and minimising kerf loss. In addition, we also shape quartz glass for specific applications using a wide range of grinding techniques, such as surface or plane grinding, external cylindrical grinding, internal cylindrical grinding, precision surface grinding and creep-feed or profile grinding. In order to implement even the most sophisticated geometries for you, we use machines and tools specially adapted to the material. For example, we use 3- and 4-axis CNC machining and carry out precise drilling work.

Application cases

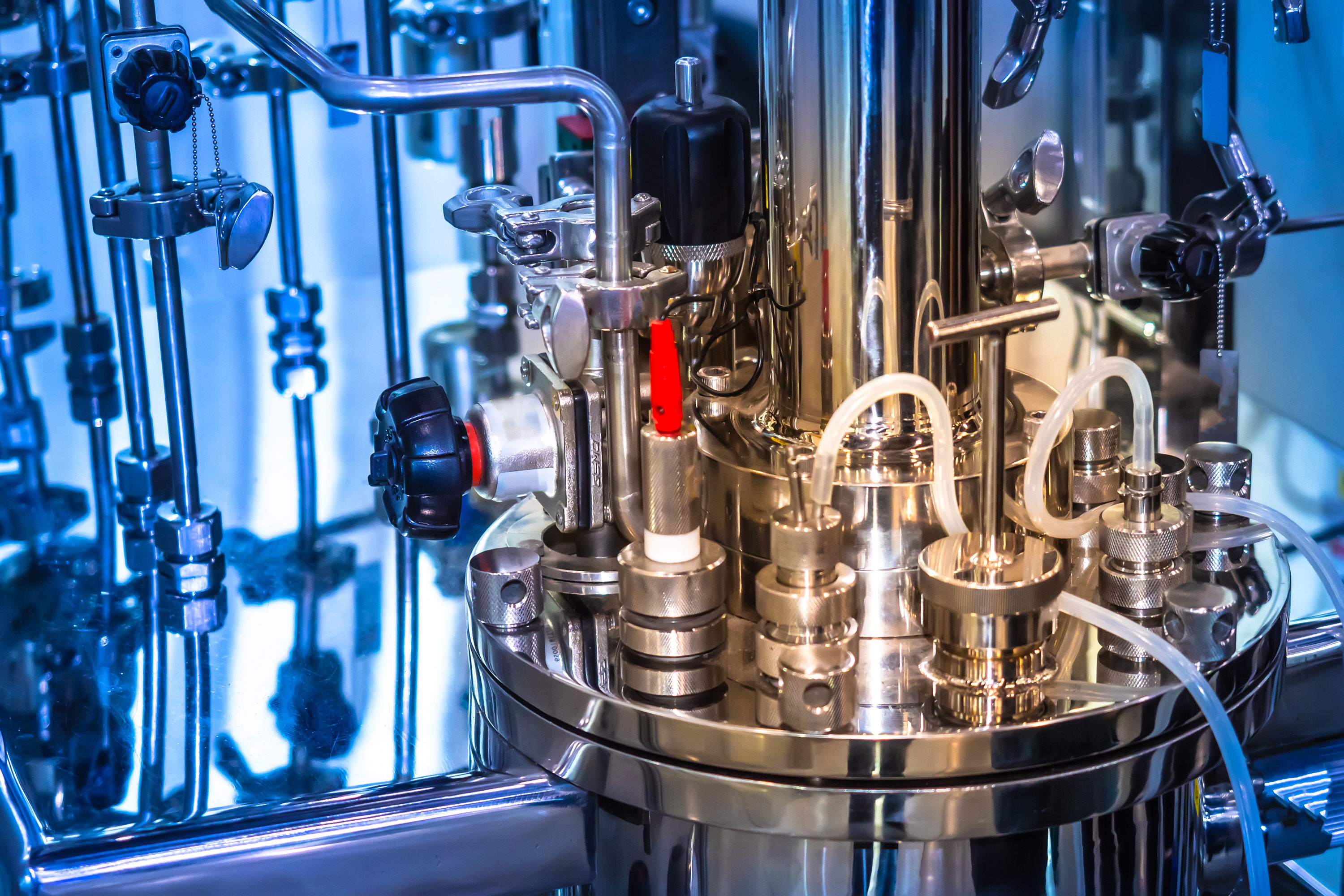

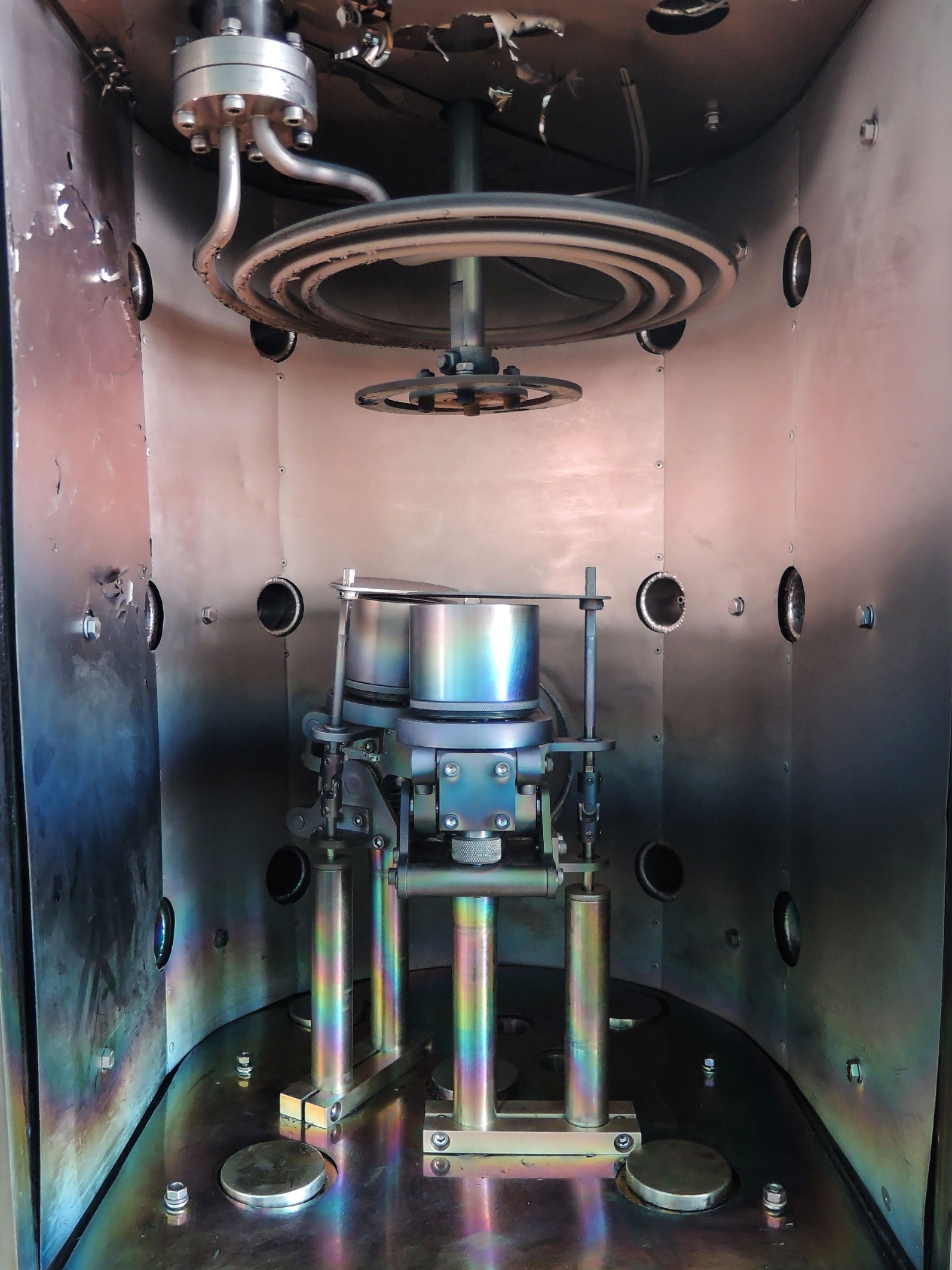

Internal assemblies for reactors

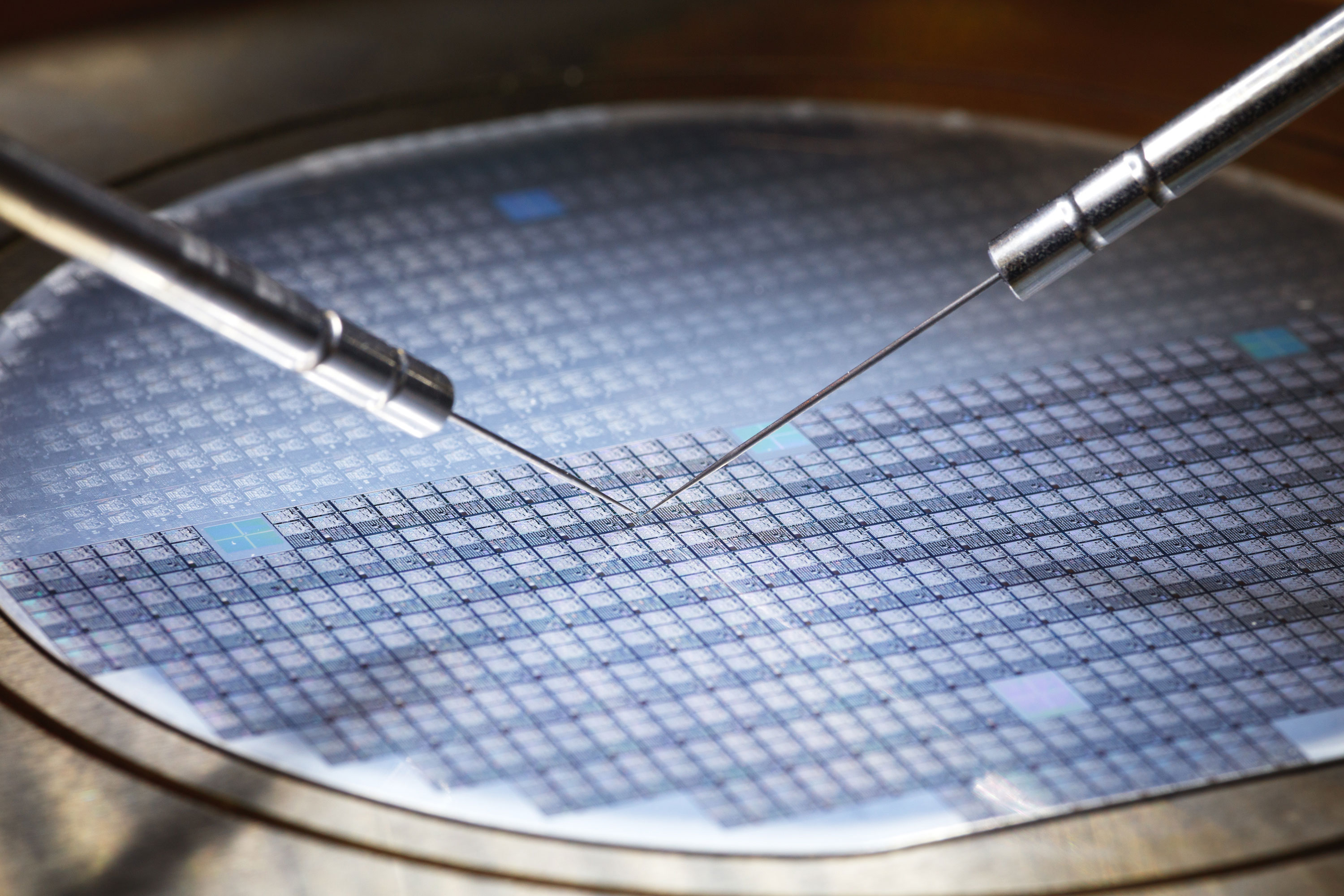

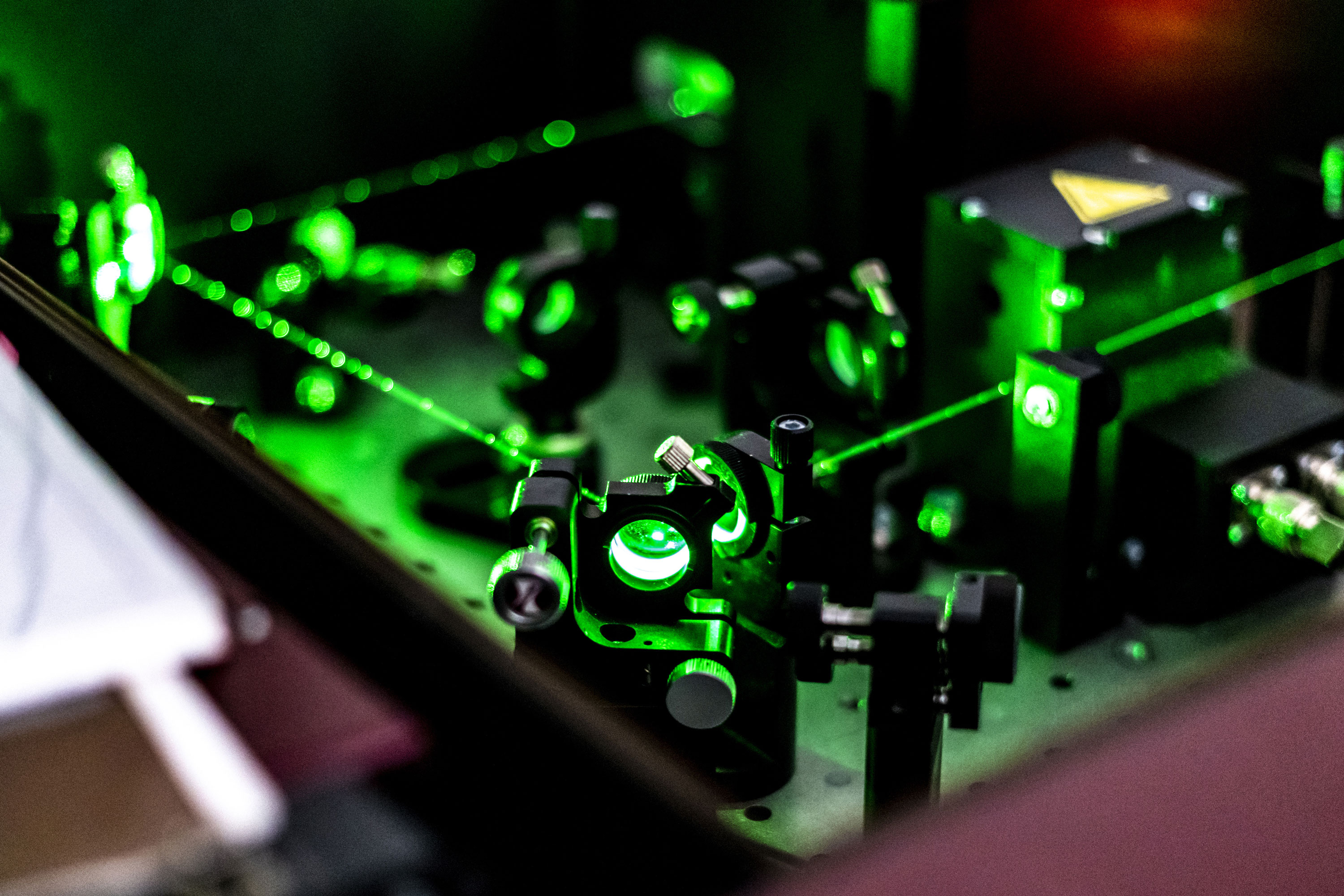

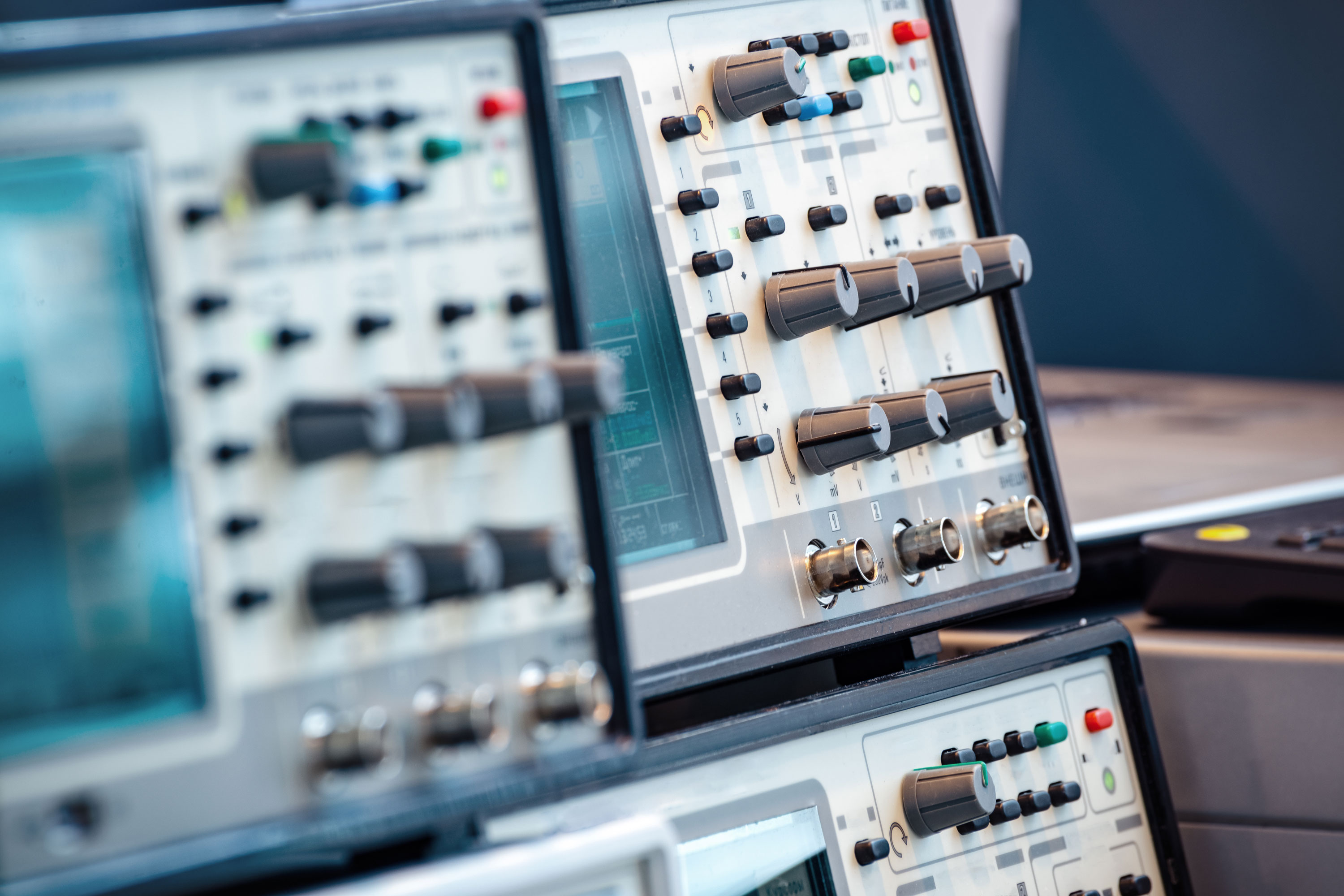

Sputtering targets

Substrate carriers

Structural components

Properties

High purity (>99.99 %)

Relatively good resistance to heat and very good resistance to a variety of process atmospheres

Good machinability

Good weldability