Optimised processes for high accuracyPrecision surface grinding

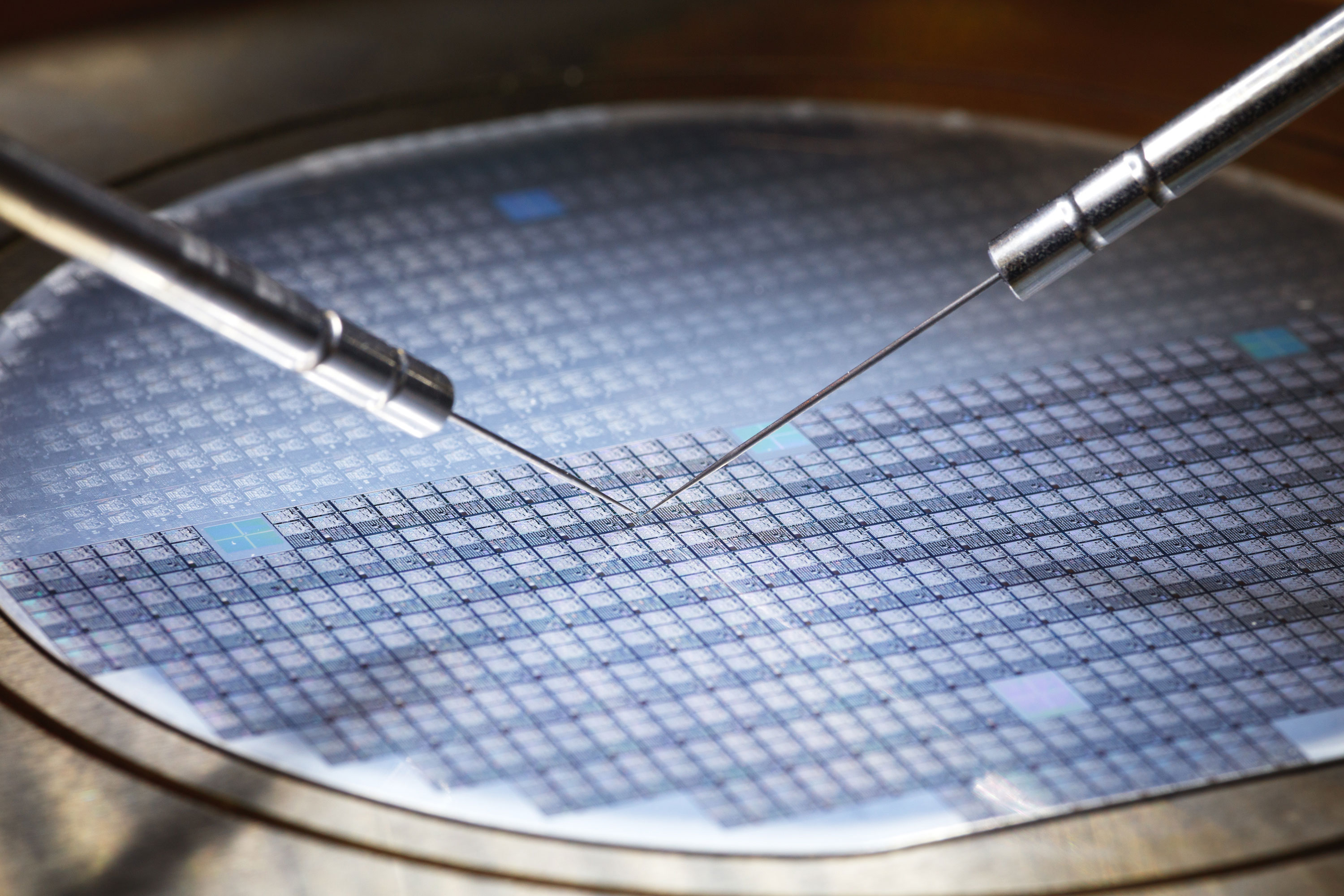

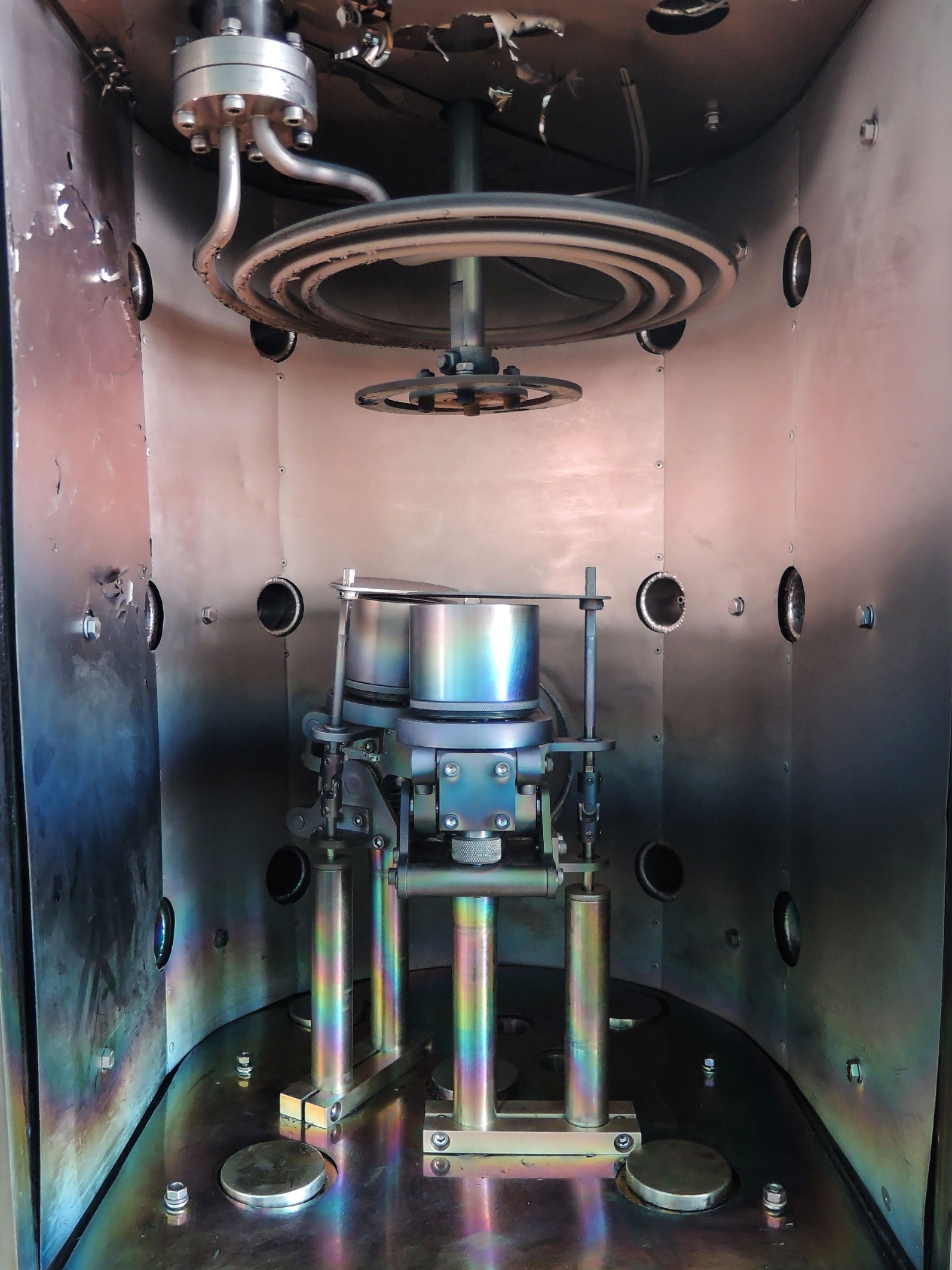

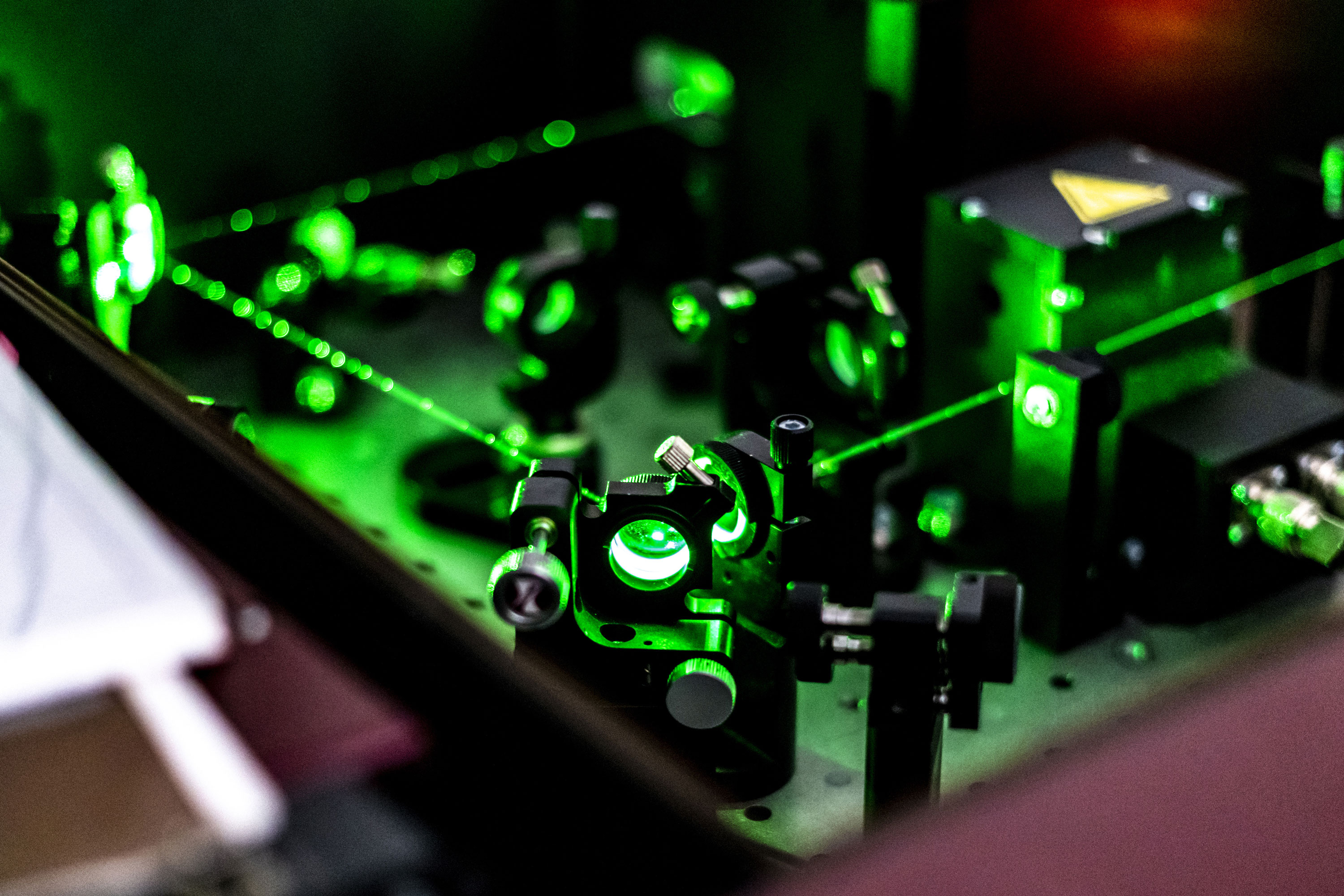

Precision surface grinding is suitable for applications requiring very high standards of accuracy and surface finish. With this method, very low levels of roughness can be achieved by means of a multi-stage process consisting of coarse pre-grinding and precise fine grinding. Precision requirements of this kind arise in various industries and applications, for example in the manufacturing of optical components, in the photovoltaic industry or in the course of research and development applications.

Grinding of hard, brittle materials calls for experience with the materials and detailed knowledge of the method. In order to achieve the desired tolerances for average roughness (Ra) and roughness depth (Rz), and at the same time prevent damage, the grinding process must be adapted to the particular properties of the hard and brittle materials such as silicon, silicon carbide, various types of glass or ceramics. In addition, process parameters for pre-grinding and fine grinding have to be set in accordance with the material properties and the application requirements. As a specialist service provider for the machining of hard and brittle materials, we have the necessary experience and the corresponding machinery.

Facts

High accuracy

Low level of roughness

Precise method

Little material removal

Technical data

Workpiece dimensions

Measurements: max. 470×200×175 mm

Accuracy

Average roughness (Ra): Pre-grinding <0.5 µm, fine grinding <0.1 µm

Roughness depth (Rz): Pre-grinding <3.5 µm, fine grinding <0.5 µm