Accurate to the millimetreResistivity measurement

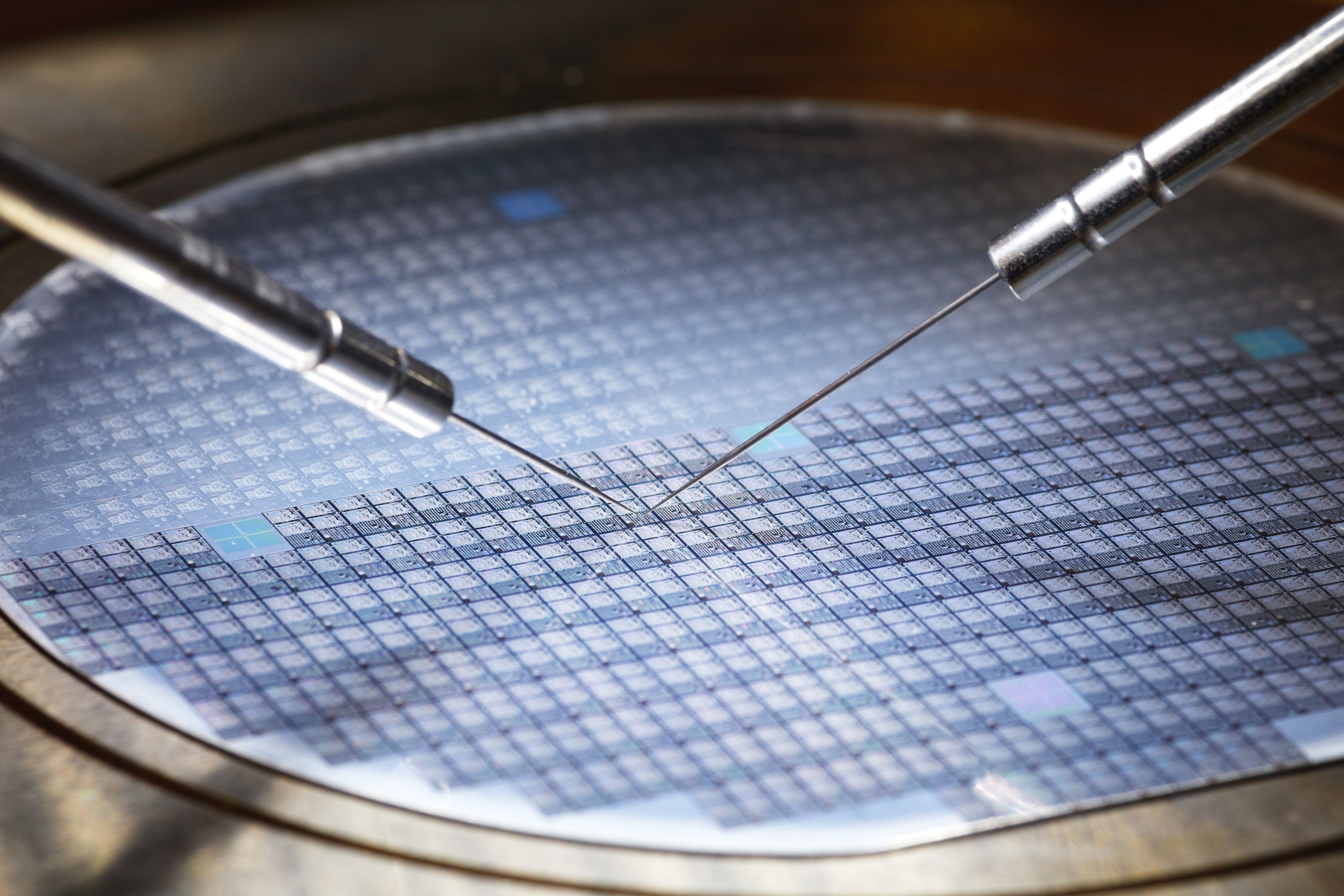

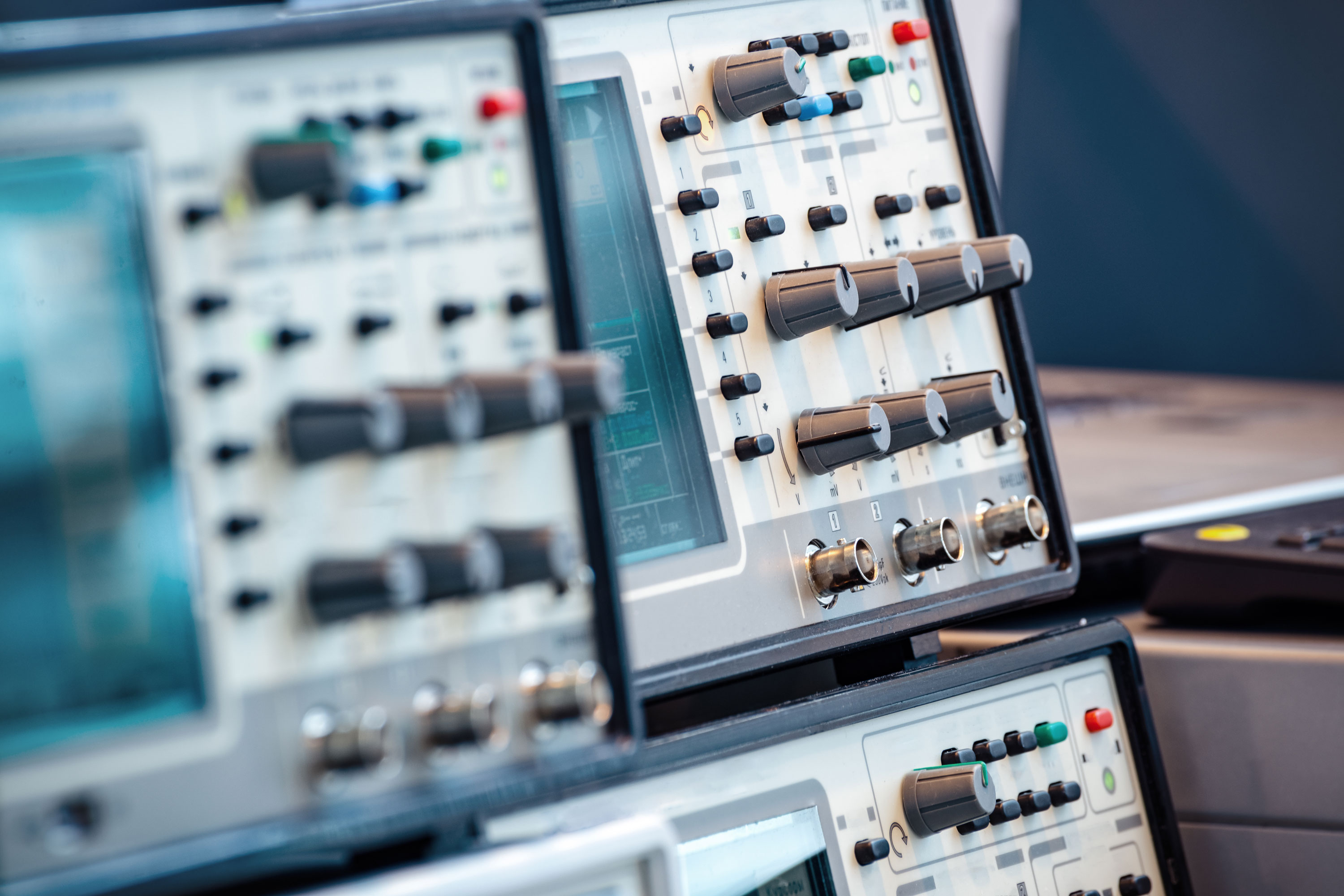

The electrical resistivity and conduction type of semiconductors, such as silicon, determine key properties for the functioning of components. A common method for determining resistivity is the four-point probe direct-current method. This permits the resistivity of a workpiece to be precisely determined – the results are decisive for the assessment of the respective properties.

With materials such as semi-metals, carbides, nitrides and ceramics, we measure the resistivity by the so-called four-point probe direct-current method according to DIN 50431. On request, we can compile detailed measurement reports with all the relevant data. We cater for customers from the optics and optoelectronics sectors, the coating industry and many fields of research and development. We determine exact material parameters – providing for seamless quality surveillance. This service is also suitable for reliable conformity testing geared to your defined specifications. As a minimum dimension, we require workpieces with at least 5 mm diameter or 5×5 mm edge length.

Facts

Exact determination of material parameters

Permits permanent quality surveillance

Suitable for testing conformity with customer specifications

Technical data

Workpiece dimensions

Diameter (Ø): min. 5 mm

Measurements: min. 5×5 mm