Resistant and durableCeramic oxides (Al₂O₃ ZrO₂)

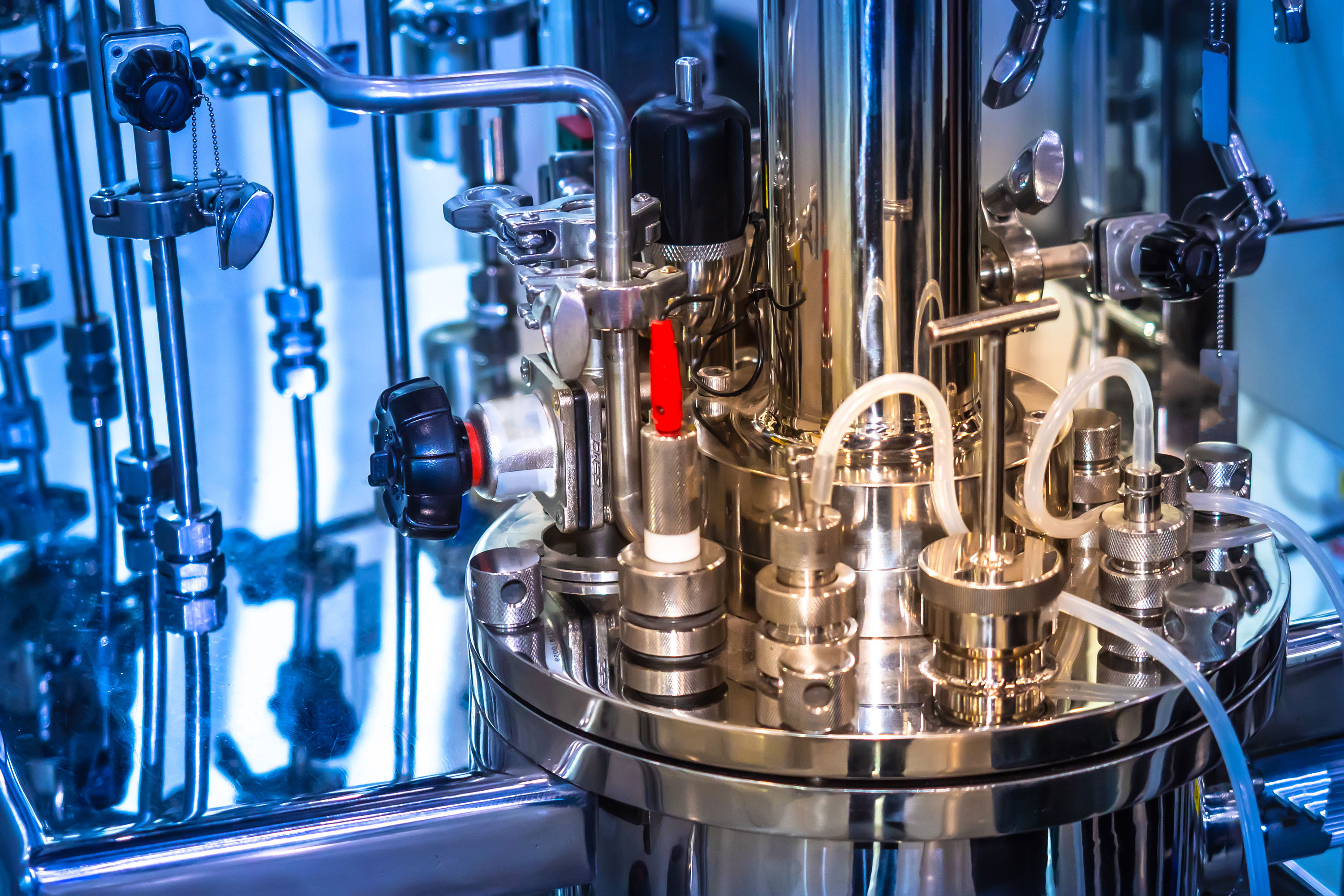

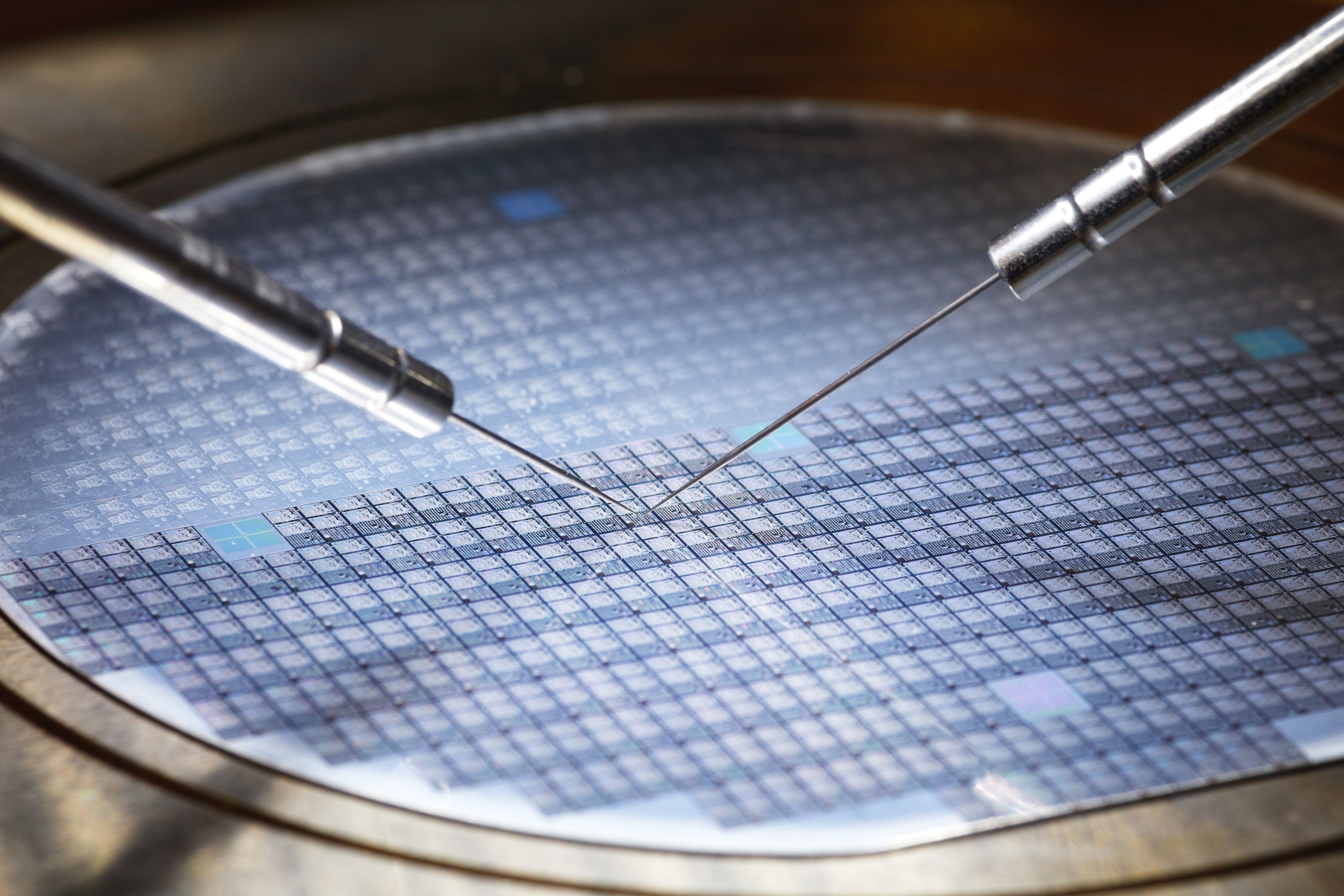

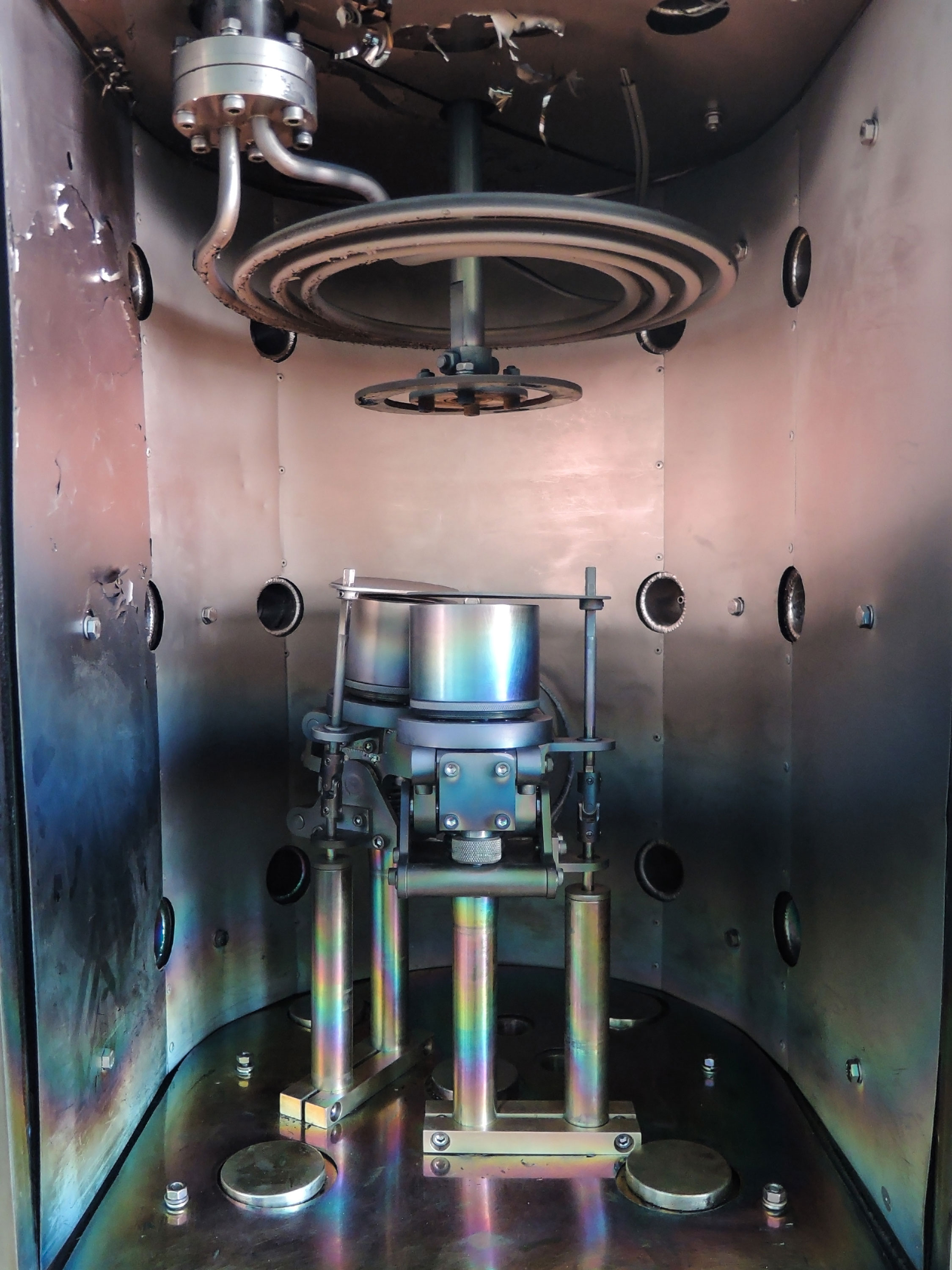

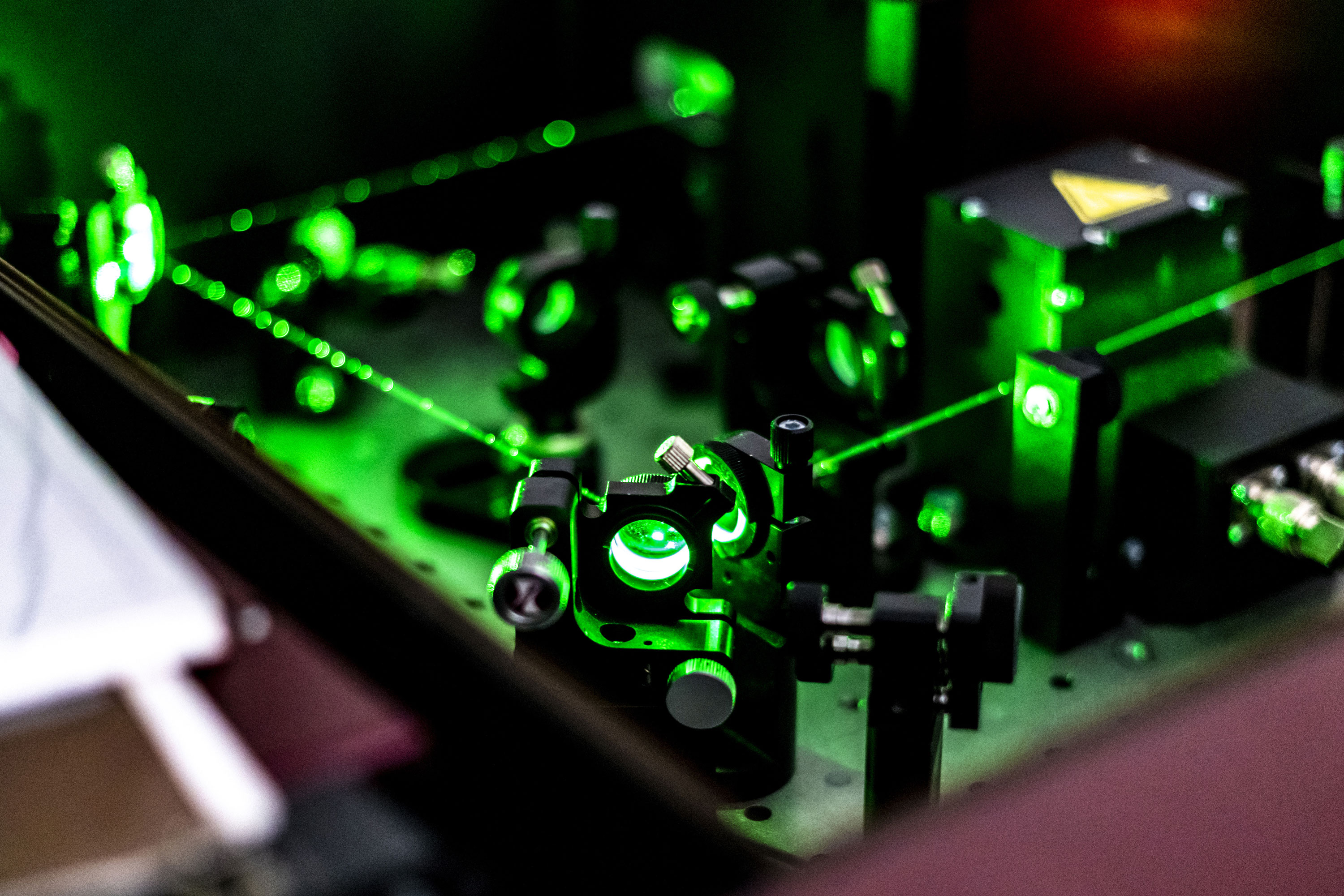

Oxide ceramics, such as aluminium oxide and zirconium oxide, are particularly suitable for the manufacturing of structural components that are subjected to high stress. Aluminium oxide, which is very pure and highly resistant to high temperatures and a vast array of chemical and physical factors, is used for highly stressed structural components, for example in reactors. These properties make the easily machinable material an indispensable raw material, above all for many applications in plant engineering and process technology, in the semiconductor industry, the primary extractive industries, research and development, and in metrology. Zirconium oxide, which is even harder, can be processed in a similar way. It is particularly resistant to the propagation of cracks and expands strongly when heated. These properties make zirconium oxide an interesting option for durable bonds between ceramics and steel.

For durable internal assemblies for reactors, nozzles and structural components of all kinds that are reliably insensitive to wear and a wide range of process atmospheres, we process both the ubiquitous aluminium oxide as well as zirconium oxide using a variety of mechanical methods. These include ID sawing, which is gentle on the material, surface or plane grinding, external and internal cylindrical grinding and profile grinding. As experienced specialists in handling hard, brittle materials such as ceramics, we use our modern 3- and 4-axis CNC machining technology to achieve even complex geometries. Our service spectrum also includes ultrasonic cleaning, laser marking, geometrical measurement and determination of surface finish.

Properties

Very good resistance to heat

Very hard

Good machinability in part