A multitude of machining optionsSilicon carbide (SiC)

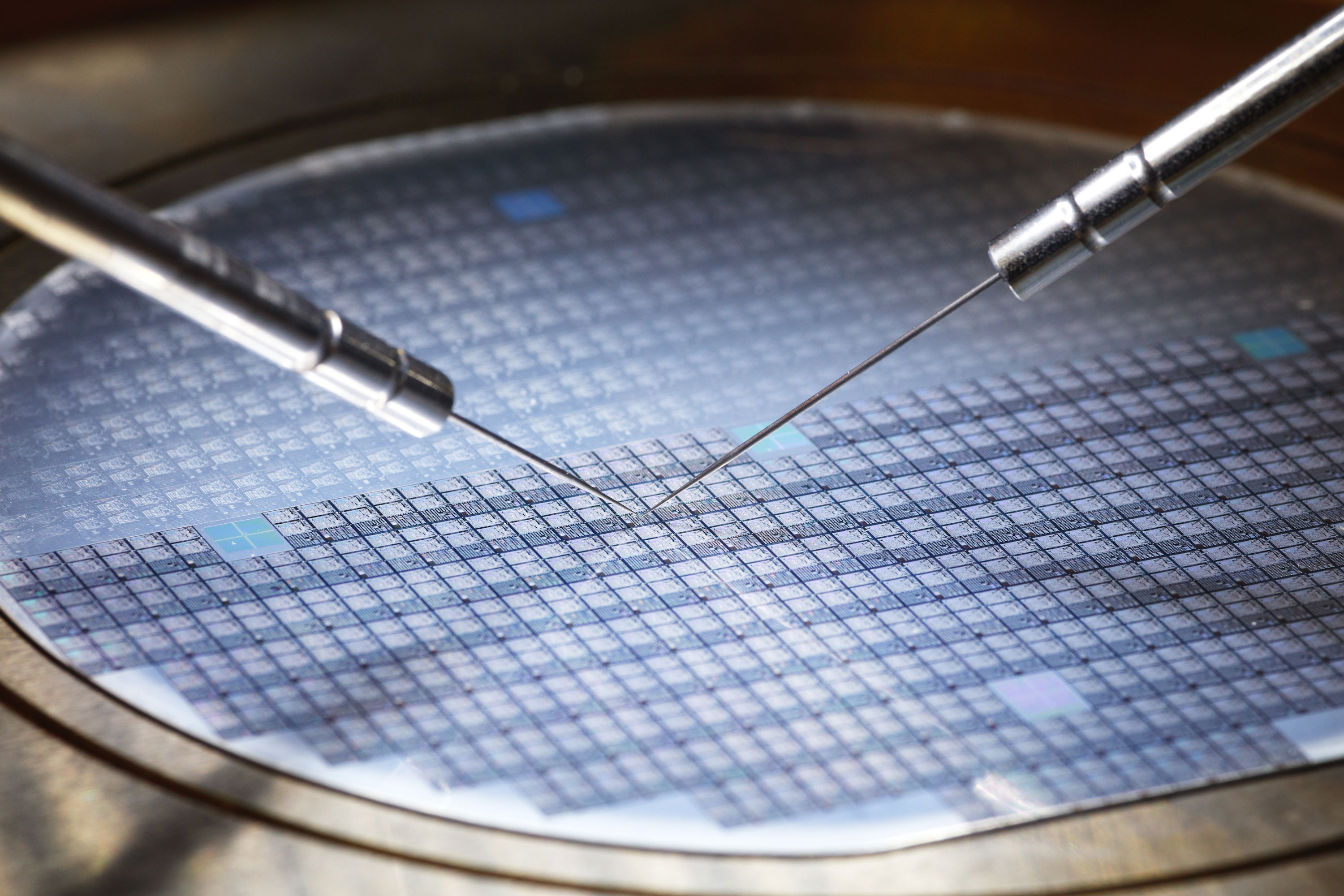

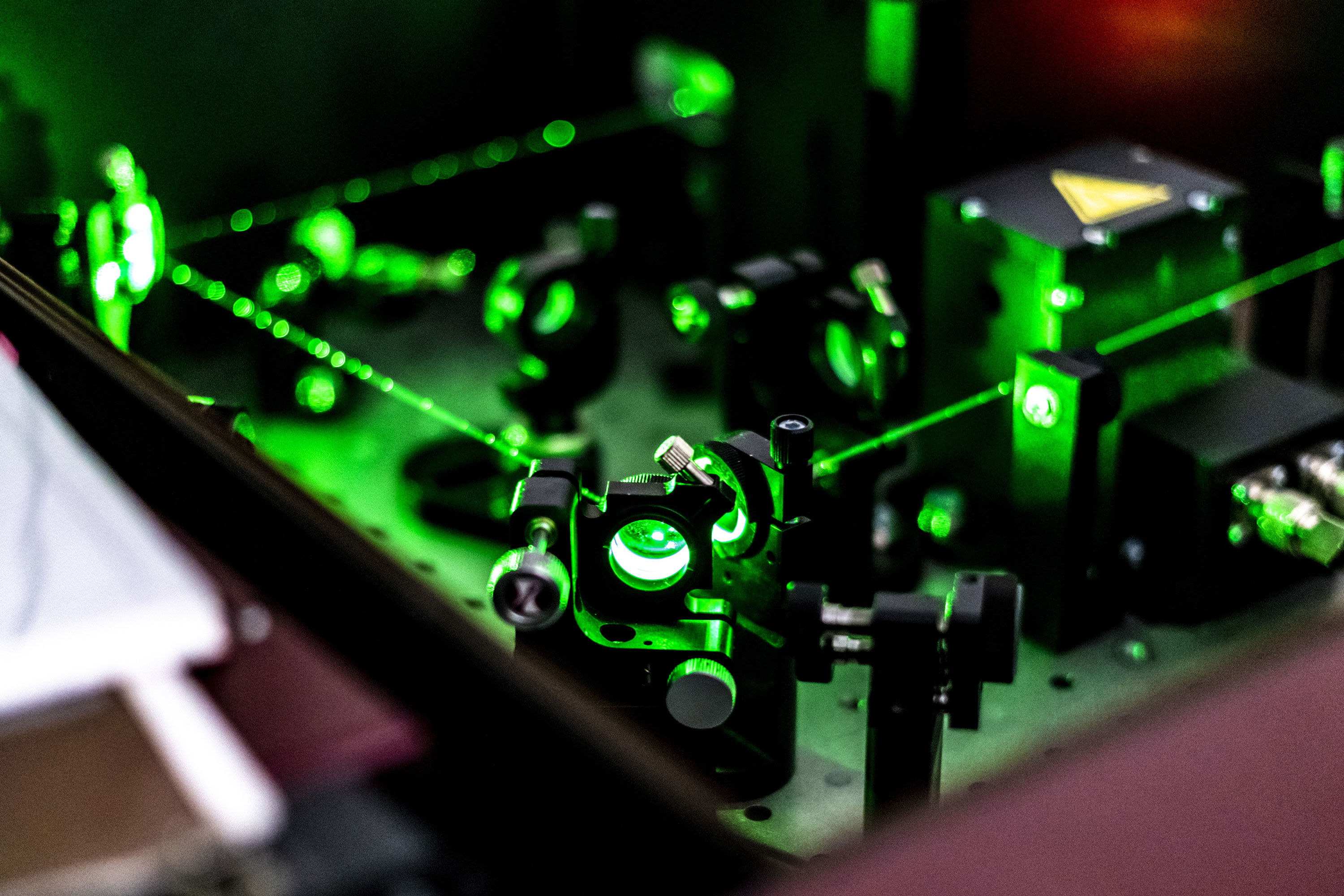

A readily available all-round raw material for particularly challenging applications: High-purity silicon carbide (SiC) permits a wide range of applications. Structural components made of the very hard material, which is highly resistant to heat and a wide variety of chemical process atmospheres, can be found, for example, in internal assemblies for reactors, and are used as non-corrosive wear parts, seals and nozzles – with the emergence of more and more new applications as of late. On account of its many positive properties, this very light material is used primarily in plant engineering and process technology, in the semiconductor industry, the primary extractive industries and in the broad field of research and development.

Also known as an “engineering ceramic", silicon carbide can be worked and processed in a multitude of ways. We use a wide range of techniques also enabling us to produce structural components with complex geometries. The mechanical processes we offer include ID sawing, surface or plane grinding, external and internal cylindrical grinding and profile grinding. As experienced specialists in dealing with hard, brittle materials, we grind and drill with our modern 3- and 4-axis CNC machining technology. And our flexibility is your advantage, because our experience and technical equipment mean that we are able to implement even time-critical orders quickly.

Application cases

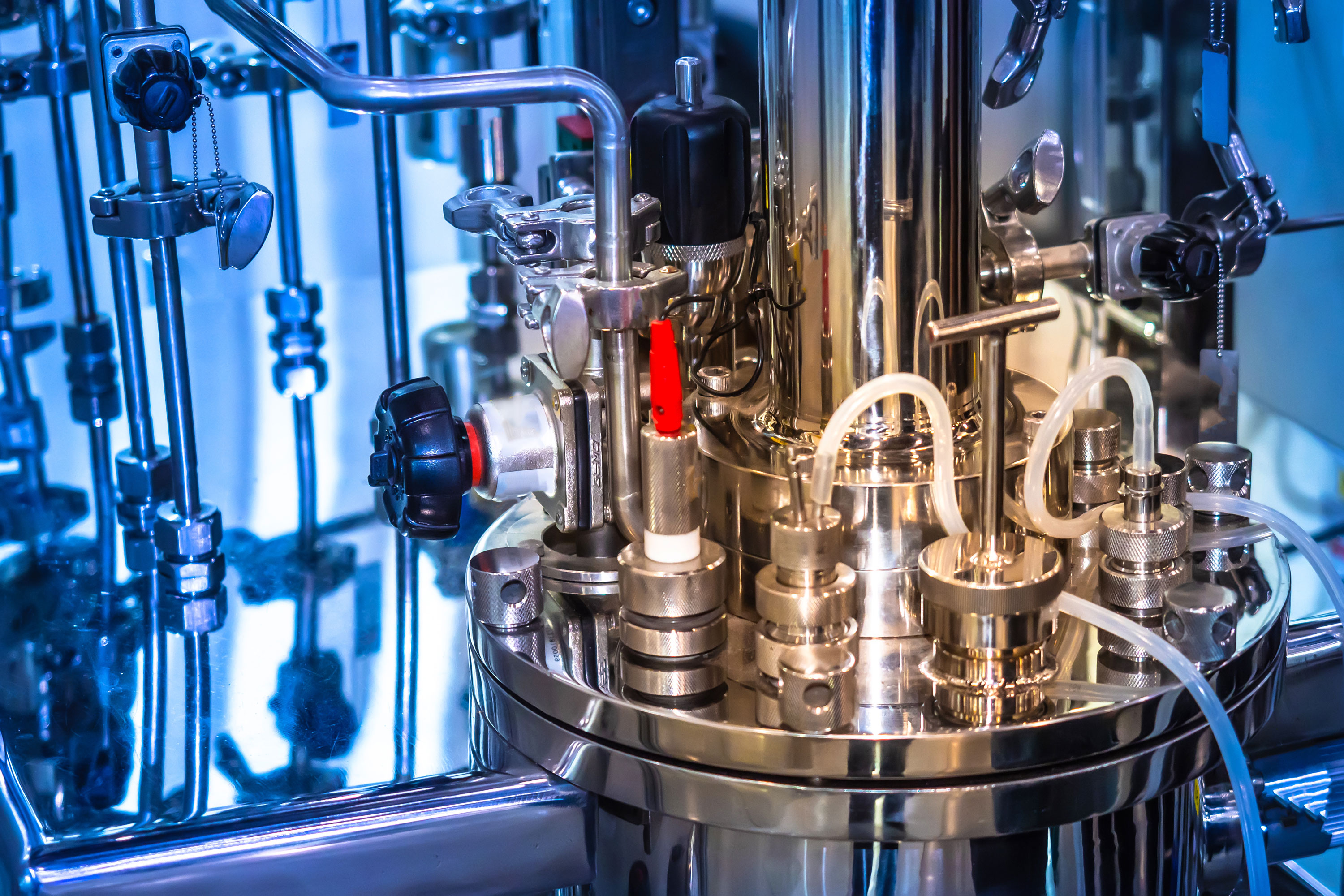

Internal assemblies for reactors

Wear-protecting parts

Seals

Nozzles

Structural components

Properties

High purity

Very good resistance to heat and a multitude of process atmospheres

Very hard

Good machinability in part